Complete Guide to Lyrlidr 8-Pack M5 Wire Rope Clamps & 4 Thimbles: Professional-Grade 304 Stainless Steel Cable Hardware

Picture this: you’re halfway through securing a critical cable assembly when your cheap wire rope clamp fails, sending hours of work tumbling down. Whether you’re rigging a sailboat, installing guy wires for an antenna, or securing cargo, the quality of your cable fasteners can make the difference between a job well done and a dangerous failure. The Lyrlidr 8-Pack M5 Wire Rope Clamps with 4 Thimbles offers a professional-grade solution that promises durability and reliability for 3/16″ cable applications.

Contents at a Glance

ToggleWhat Makes Lyrlidr Wire Rope Clamps Stand Out?

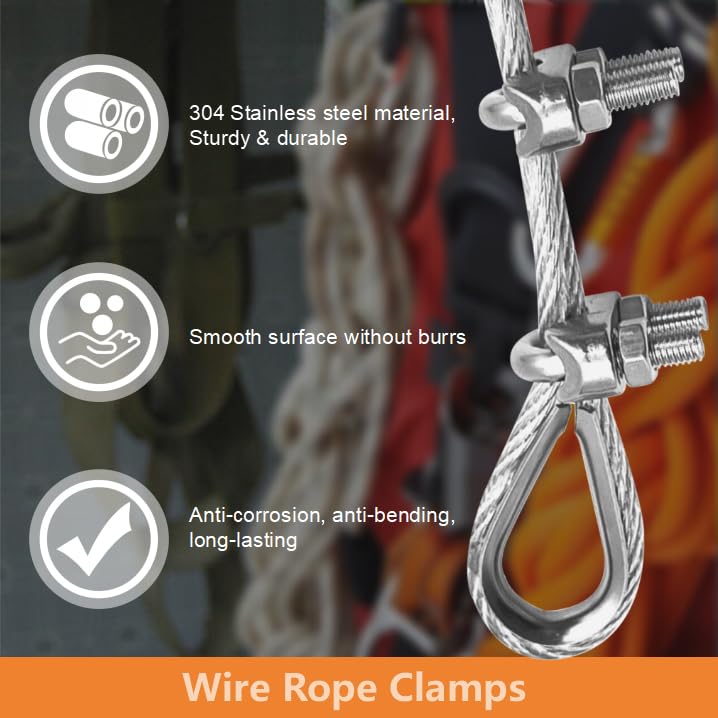

The Lyrlidr M5 wire rope clamp system combines premium 304 stainless steel construction with thoughtful engineering designed for real-world applications. These U-bolt saddle fasteners aren’t just another hardware store option – they’re purpose-built for demanding environments where cable security cannot be compromised.

Key Features and Specifications

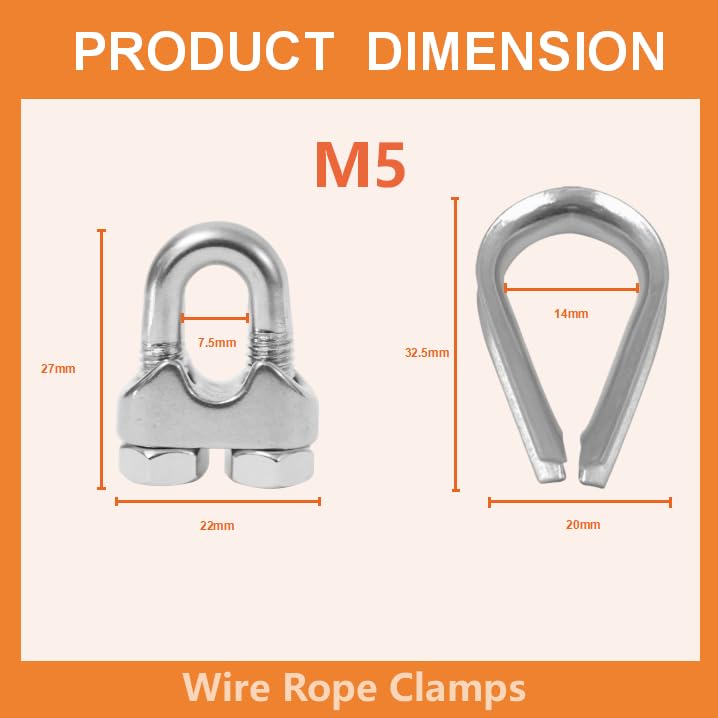

The complete kit includes eight M5 wire rope clamps and four cable thimbles, specifically engineered for 3/16″ (5mm) wire rope applications. The 304 stainless steel construction provides superior corrosion resistance compared to standard steel alternatives, making these clamps suitable for both indoor and outdoor installations.

Each clamp features a U-bolt design with saddle plates that distribute load evenly across the cable surface, reducing stress concentrations that could lead to premature wire rope failure. The included thimbles protect the cable from sharp bends and wear points, extending overall system life.

The M5 threading ensures secure attachment while allowing for precise tension adjustment during installation. This standardized sizing also makes replacement parts readily available when needed for maintenance or expansion projects.

Understanding Wire Rope Clamp Applications

Wire rope clamps serve as the backbone of countless industrial, marine, and residential cable systems. From securing sailboat rigging to anchoring guy wires for communication towers, these seemingly simple components carry enormous responsibility.

Marine and Boating Applications

In marine environments, stainless steel wire rope clamps face constant exposure to saltwater, UV radiation, and mechanical stress. The 304 stainless steel construction of Lyrlidr clamps provides excellent corrosion resistance, though 316 stainless steel offers even better performance in harsh marine conditions.

Sailors commonly use these clamps for lifeline installations, boom vangs, and standing rigging modifications. The ability to create secure loops and connections without specialized tools makes them invaluable for onboard repairs and modifications.

Construction and Industrial Uses

Construction professionals rely on wire rope clamps for temporary and permanent installations, including safety cables, suspended loads, and architectural features. The consistent clamping force provided by properly torqued M5 hardware ensures reliable performance under dynamic loads.

Industrial applications range from conveyor systems to overhead crane installations, where cable terminations must withstand repetitive loading cycles without loosening or failing.

Residential and DIY Projects

Homeowners discover wire rope clamps useful for deck railing systems, clotheslines, antenna guy wires, and tree support cables. The professional appearance of stainless steel hardware complements outdoor installations while providing long-term durability.

Pros and Cons of Lyrlidr Wire Rope Clamps

Advantages

Superior Corrosion Resistance: The 304 stainless steel construction significantly outperforms galvanized steel alternatives in outdoor environments. This translates to longer service life and reduced maintenance requirements, particularly important for hard-to-reach installations.

Complete Kit Convenience: Including both clamps and thimbles in one package eliminates the need for separate purchases and ensures component compatibility. Many competitors sell clamps separately, leading to mismatched hardware and potential performance issues.

Professional-Grade Construction: The precision manufacturing and consistent thread quality reflect attention to detail often missing in budget alternatives. Proper thread engagement and saddle plate alignment contribute to reliable clamping force distribution.

Versatile Application Range: While optimized for 3/16″ cable, these clamps accommodate slight size variations common in real-world installations. This flexibility reduces inventory requirements for contractors managing multiple projects.

Cost-Effective Value: When compared to individual purchases of equivalent quality components, the 8-pack configuration provides significant savings for projects requiring multiple terminations.

Limitations

Size Specificity: The M5 threading and 3/16″ cable optimization limit compatibility with larger or smaller wire rope sizes. Users working with mixed cable diameters may need multiple clamp sizes.

Installation Skill Requirements: Proper installation requires an understanding of cable termination techniques, torque specifications, and safety factors. Inexperienced users might compromise performance through incorrect installation.

Initial Investment: While cost-effective for multi-clamp projects, the 8-pack quantity might exceed requirements for simple single-point applications, representing unnecessary upfront expense.

Limited Load Data: Unlike specialized rigging hardware, general-purpose wire rope clamps may not include detailed working load limits for specific applications, requiring users to apply appropriate safety factors.

Proper Installation Techniques

Successful wire rope clamp installation depends on following established procedures that ensure maximum holding strength and cable life. The “dead end” installation method places the U-bolt on the short, non-load-bearing side of the cable, while the saddle contacts the long, load-bearing portion.

Step-by-Step Installation Process

Begin by determining the required number of clamps based on cable diameter and application loads. Industry standards typically specify minimum quantities and spacing requirements for different wire rope sizes.

Position the first clamp approximately one cable diameter from the desired termination point. Apply initial finger-tight pressure to all nuts before final tightening to prevent cable distortion.

Tighten clamps in sequence, applying specified torque values gradually rather than fully tightening each clamp individually. This approach prevents cable damage and ensures even load distribution across multiple termination points.

Common Installation Mistakes

Reversing the clamp orientation represents the most frequent error, placing the U-bolt against the load-bearing cable portion. This configuration significantly reduces holding strength and may cause premature failure.

Over-tightening creates stress concentrations that can damage individual wire strands, while under-tightening allows slippage under load. Using a torque wrench eliminates guesswork and ensures consistent installation quality.

Insufficient clamp quantity or improper spacing reduces overall termination strength. Following manufacturer recommendations and industry standards prevents these critical oversights.

Maintenance and Longevity

Stainless steel wire rope clamps require minimal maintenance when properly installed, but periodic inspection ensures continued reliability. Visual examination should identify signs of corrosion, mechanical wear, or loosening hardware.

Marine applications benefit from freshwater rinsing to remove salt deposits that could accelerate corrosion in crevices or threaded areas. While 304 stainless steel provides good corrosion resistance, regular cleaning extends service life in harsh environments.

Retightening clamps after initial loading allows cable settling and ensures a maintained clamping force. Many installations benefit from inspection after the first month of service, followed by annual checks for critical applications.

Frequently Asked Questions

Q: How many clamps do I need for a 3/16″ cable termination? A: Industry standards typically require a minimum of three clamps for 3/16″ wire rope applications. The exact number depends on load requirements and safety factors for your specific application.

Q: Can these clamps be used with coated or vinyl-covered cable? A: Yes, but the coating may need to be removed at clamp locations to ensure proper grip. Vinyl coating can compress under clamping force, potentially reducing holding strength.

Q: What’s the difference between 304 and 316 stainless steel for marine use? A: While 304 stainless steel offers good corrosion resistance, 316 stainless steel provides superior performance in marine environments due to added molybdenum content. For critical marine applications, consider upgrading to 316 stainless steel hardware.

Q: How tight should I torque the clamp nuts? A: Specific torque values depend on cable construction and application requirements. As a general guideline, tighten until the cable shows slight deformation at the saddle contact points, then add one-quarter turn.

Q: Are thimbles always necessary? A: Thimbles aren’t required for every application, but significantly extend cable life in high-load or high-cycle installations. They’re essential when forming loops around hardware or creating connections subject to angular loading.

Q: Can I reuse clamps after removing them? A: Clamps can typically be reused if threads and saddle surfaces remain undamaged. However, cables often show permanent deformation at clamp locations, requiring fresh cable sections for optimal performance.

Making the Right Choice for Your Project

The Lyrlidr 8-Pack M5 Wire Rope Clamps with 4 Thimbles represents a solid investment for projects requiring reliable 3/16″ cable terminations. The combination of 304 stainless steel construction, complete kit convenience, and competitive pricing makes this set particularly attractive for contractors and serious DIY enthusiasts.

Consider your specific application requirements, environmental conditions, and load demands when evaluating this product. While these clamps excel in general-purpose applications, specialized rigging situations might benefit from certified lifting hardware with documented load ratings.

Transform Your Cable Projects Today

Don’t let inferior hardware compromise your next installation. The Lyrlidr 8-Pack M5 Wire Rope Clamps provide the professional-grade reliability your projects deserve. Whether you’re securing a boat’s lifelines, installing antenna guy wires, or tackling industrial cable terminations, this complete kit delivers the quality and convenience that separates successful installations from costly failures.

Ready to experience the difference that quality cable hardware makes? Order your Lyrlidr 8-Pack M5 Wire Rope Clamps with 4 Thimbles today and join thousands of satisfied customers who’ve discovered the peace of mind that comes with professional-grade cable terminations. Your projects – and your reputation – deserve nothing less than the best.