Essential Rope Maintenance Tips for Shipping, Fishing, and Hauling

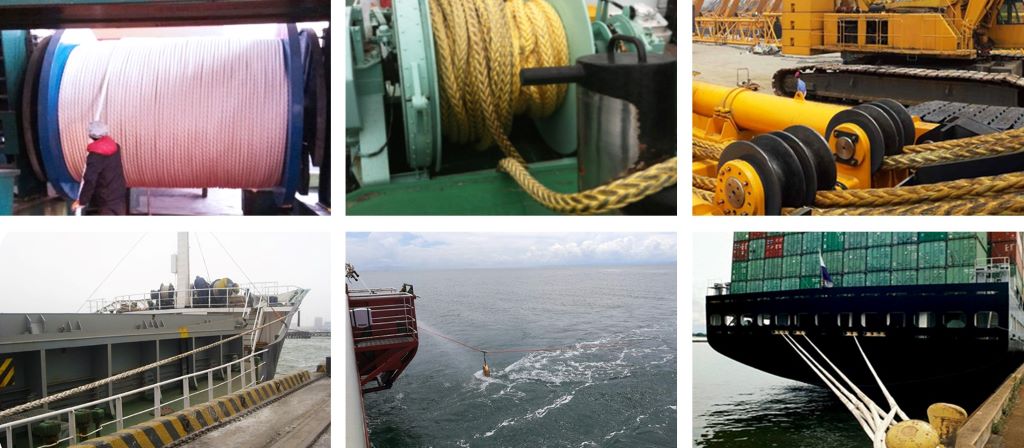

Ropes are the unsung heroes of maritime, industrial, and outdoor operations. Whether you’re securing cargo on a freighter, hauling nets on a fishing vessel, or towing heavy loads across rugged terrain, your rope is only as reliable as the care it receives. Neglecting rope maintenance can lead to fraying, snapping, and catastrophic failures. This guide dives deep into essential rope maintenance tips for shipping, fishing, and hauling—backed by expert insights, real-world data, and actionable advice.

Contents at a Glance

ToggleWhy Rope Maintenance Matters More Than You Think

Ropes endure extreme stress, exposure to harsh elements, and repetitive use. According to Access Ropes, UV radiation alone can reduce a rope’s strength by up to 15%. Saltwater, chemicals, and abrasion further accelerate wear. In shipping and fishing, a single rope failure can cost thousands in damages or even lives.

In hauling operations, ropes often bear loads exceeding several tons. A weakened rope can snap under pressure, causing injury or equipment loss. Therefore, consistent maintenance isn’t optional—it’s a safety imperative.

-

Regular Inspection: Spot Trouble Before It Strikes

Before every use, inspect your ropes thoroughly. Look for:

- Fraying or broken strands

- Discoloration or stiffness

- Flattened or kinked sections

- Signs of chemical exposure or mildew

Experts at ROPE.com recommend checking both ends and the middle, as damage often hides in coiled sections. If you notice any of these signs, retire the rope or downgrade it to non-critical tasks.

-

Cleaning: Salt, Dirt, and Chemicals Are Silent Killers

Saltwater is particularly corrosive. It crystallizes within rope fibers, reducing flexibility and causing internal abrasion. After each use in marine environments, rinse ropes with fresh water. Use mild detergent for deeper cleans, especially in fishing operations where organic residue builds up.

Avoid harsh chemicals. Even petroleum-based products can degrade synthetic ropes. If exposure occurs, test the rope’s tensile strength before reuse.

-

Storage: Where You Keep Your Rope Determines Its Lifespan

Improper storage is a leading cause of premature rope failure. Store ropes:

- In a cool, dry, ventilated space

- Away from direct sunlight

- Off the ground to avoid grit and moisture

- In breathable rope bags—not sealed containers

According to GZ Industrial Supplies, UV exposure and mildew can weaken ropes even when not in use. Natural fiber ropes like manila or sisal are especially vulnerable to mold and rot.

-

Load Management: Know Your Rope’s Limits

Every rope has a rated load capacity. Exceeding it—even once—can cause micro-damage that compromises future performance. In shipping and hauling, always calculate the working load limit (WLL) and apply a safety factor of at least 5:1.

For example, if a rope is rated for 1,000 lbs, don’t exceed 200 lbs in dynamic loads. Sudden jerks or drops multiply stress. Use load-distributing knots and avoid sharp angles that concentrate force.

-

Avoid Abrasion: Friction Is a Rope’s Worst Enemy

Ropes rubbing against metal, concrete, or rough surfaces wear down quickly. Use chafe guards, pulleys, or sleeves in high-friction zones. In fishing, net ropes often rub against boat edges—install rubber or plastic buffers to reduce wear.

Routine repositioning also helps. Don’t let ropes sit in the same groove for extended periods. Rotate them to distribute wear evenly.

-

Retire Ropes Wisely: Don’t Wait for Failure

Ropes don’t last forever. Even with perfect care, they degrade. Here’s a general lifespan guide from Access Ropes:

- Intensive use: 3 months to 1 year

- Weekly use: 2 to 3 years

- Occasional use: Up to 5 years

Invisible damage like tensional fatigue or polymer creep can’t be seen, but it weakens the rope. If in doubt, retire the rope or send it for professional testing.

-

Rope Type Matters: Tailor Maintenance to Material

Different ropes require different care:

| Rope Type | Strengths | Weaknesses | Maintenance Tips |

| Nylon | High elasticity, strong | UV degradation | Store in shade, avoid chemicals |

| Polyester | UV resistant, low stretch | Stiffens over time | Rinse after saltwater exposure |

| Polypropylene | Lightweight, floats | Poor UV resistance | Replace frequently, store indoors |

| Manila/Sisal | Biodegradable, good grip | Susceptible to rot and mildew | Keep dry, inspect for mold |

Choose the right rope for the job and adjust your maintenance routine accordingly.

Featured Snippet: What Are the Best Rope Maintenance Tips for Marine and Industrial Use?

Q: What are the best rope maintenance tips for marine and industrial use?

A: To maintain ropes used in shipping, fishing, and hauling, follow these essential tips:

- Inspect regularly for fraying, stiffness, and discoloration.

- Clean with fresh water after exposure to salt or chemicals.

- Store in cool, dry places away from sunlight and moisture.

- Avoid overloading beyond rated capacity.

- Use chafe guards to prevent abrasion.

- Retire ropes based on usage frequency and visible wear.

- Tailor care to rope material—natural fibers need more protection from moisture, while synthetics degrade under UV.

Proper maintenance ensures safety, longevity, and optimal performance in demanding environments.

FAQs

- How often should I inspect my ropes?

Inspect ropes before every use, especially in critical applications like shipping or towing. - Can I use bleach to clean my ropes?

No. Bleach weakens rope fibers. Use mild detergents and rinse thoroughly. - What’s the best way to dry a rope?

Air-dry in a shaded, ventilated area. Avoid direct sunlight and never use a dryer. - How do I know when to retire a rope?

Retire ropes showing fraying, stiffness, or after their expected lifespan based on usage. - Is it safe to use ropes with minor damage?

Only for non-critical tasks. Never use damaged ropes for lifting or towing. - What’s the difference between static and dynamic ropes?

Static ropes have low stretch and are ideal for hauling. Dynamic ropes stretch under load, used in climbing. - Can I store ropes in sealed containers?

No. Ropes need airflow to prevent mildew. Use breathable bags or open shelves.

Final Thought

Rope maintenance isn’t glamorous, but it’s vital. Whether you’re navigating open seas, hauling heavy loads, or casting nets at dawn, your rope is your lifeline. Treat it with care, and it will serve you faithfully. Neglect it, and you risk safety, efficiency, and cost. Read More: Fishing Rope Maintenance: Tips for Long-Lasting Performance

Call to Action

Ready to extend the life of your ropes and boost operational safety? Start by auditing your current rope inventory. Clean, inspect, and store them properly. Share this guide with your crew or team, and make rope maintenance a standard practice. For more expert tips, visit Access Ropes or ROPE.com. Your ropes—and your bottom line—will thank you.