Rope for Pulling Down Trees: Strength Meets Safety

For pulling down trees, a strong, durable rope designed for rigging or arborist work is essential. Choose ropes with high tensile strength to ensure safety and efficiency.

Contents at a Glance

ToggleRemoving trees is a task that requires the right tools and techniques. One crucial piece of equipment is the rope, which must be sturdy enough to handle the immense forces involved in tree pulling. Arborists and rigging professionals typically use ropes made from materials like polyester or polypropylene because of their resistance to abrasion and their ability to withstand heavy loads.

It’s not just about having a strong rope; the diameter, flexibility, and knot-holding capacity are also vital factors to consider. Safety is paramount in tree removal, and the correct rope can mean the difference between a job well done and an accident waiting to happen. This is why it’s important to select a rope that is specifically designed for arboricultural or rigging purposes, ensuring it can handle the dynamic stresses of pulling down trees.

Credit: m.youtube.com

Introduction To Arborist Ropes

Ropes play a crucial role in arboriculture, particularly when pulling down trees safely and efficiently. The right arborist rope can mean the difference between a successful job and a potential hazard. Arborists rely on ropes with high strength, durability, and flexibility to manage the immense forces at play.

Essential Qualities

When selecting an arborist rope, certain qualities are non-negotiable:

- Durability: Ropes must withstand rough bark and harsh outdoor elements.

- Strength: They should handle heavy loads without breaking.

- Flexibility: Ropes need to bend around branches without kinking.

- Grip: A good rope offers a firm grip for secure knotting.

- Low Stretch: Minimal elongation ensures better control over tree movement.

Types Of Ropes Used

Arborists use two primary types of ropes:

| Rope Type | Features | Use Cases |

|---|---|---|

| Static Ropes | Little to no stretch, high strength | Rigging, lowering heavy branches |

| Dynamic Ropes | More stretch, absorbs shock loads | Climbing, where flexibility is key |

Each rope serves a specific purpose. Static ropes are ideal for rigging and support. Dynamic ropes, with their ability to stretch, are better for tasks that require more give, such as climbing.

Credit: www.chegg.com

Material Matters

Choosing the right rope to pull down trees is crucial. The material of the rope affects strength, flexibility, and safety. Let’s dive into the materials that make ropes reliable for this tough job.

Nylon Vs. Polyester

Nylon ropes are known for their elasticity. This stretchiness absorbs shock loads well. When pulling trees, this feature helps reduce snap-back risks. Nylon ropes are strong and last long.

Polyester ropes have less stretch, making them more stable. They resist abrasion and sun damage better than nylon. This makes them good for outdoor tasks.

Here’s a quick comparison:

| Feature | Nylon | Polyester |

|---|---|---|

| Stretch | High | Low |

| Strength | Strong | Strong |

| UV Resistance | Low | High |

| Water Absorption | High | Low |

| Best Use | Dynamic Loads | Static Loads |

Blended Fibers

Some ropes mix materials to get the best of both worlds. Blended ropes can offer the stretch of nylon and the durability of polyester. This combination can be ideal for tree pulling.

- Blended ropes are versatile.

- They balance stretch and stability.

- They are good for different weather conditions.

Blended ropes can be a smart choice for their adaptability and resilience.

Strength Specifications

Strength Specifications are critical when selecting rope for pulling down trees. The rope must withstand immense forces to ensure safety and efficiency during tree removal. Understanding the rope’s tensile strength and working load limit is essential. These measures prevent accidents and equipment damage.

Tensile Strength

Tensile strength refers to the maximum stress a rope can bear before breaking. It’s measured in pounds or kilograms. The rope’s material and construction determine this strength. A high tensile strength is vital for pulling down large trees.

- Polypropylene ropes offer good tensile strength and float in water.

- Nylon ropes excel in strength and elasticity, ideal for dynamic tension.

- Manila ropes provide natural fiber strength, suitable for static loads.

Working Load Limit

The Working Load Limit (WLL) is the maximum safe load a rope can handle. It’s a fraction of the tensile strength, often one-fifth. Always follow the WLL to prevent rope failure.

| Rope Type | Working Load Limit |

|---|---|

| Polypropylene | 20% of Tensile Strength |

| Nylon | 20% of Tensile Strength |

| Manila | 20% of Tensile Strength |

Remember: Always check the rope’s WLL before use. This ensures the rope can handle the weight of the tree without breaking.

Credit: thesprucetunnel.wordpress.com

Safety Considerations

Safety Considerations are crucial when using rope for pulling down trees. The right precautions prevent accidents and ensure a smooth operation.

Breaking Points

Understanding the breaking points of ropes is essential. This knowledge helps avoid rope failure during use. Here’s a simple guide:

- Check the rope’s strength rating before use.

- Match it against the weight of the tree to be pulled.

- Use a rope with a higher strength rating than needed.

Wear And Tear Inspection

Regular inspections keep the rope in good working condition. Follow these steps:

- Inspect the rope for any visible damage like frays or cuts.

- Look for signs of weathering or chemical damage.

- Replace the rope if any damage is detected.

These safety checks help ensure the rope can handle the task without breaking. This protects everyone involved.

Rope Diameter And Length

Understanding the importance of rope diameter and length is critical when pulling down trees. The right rope ensures safety and efficiency during the process. Let’s dive into the specifics of choosing the best diameter and determining the ideal length for tree pulling ropes.

Choosing The Right Diameter

The diameter of the rope directly impacts its strength and durability. A rope too thin might snap under tension, while a thick rope can be cumbersome.

- Less than 1/2 inch: Suitable for small tree limbs.

- 1/2 inch to 3/4 inch: Works well for medium-sized trees.

- Over 3/4 inch: Best for large and heavy trees.

Material matters too. Polyester and nylon are popular for their strength and stretch.

Determining Ideal Length

Rope length is just as crucial as diameter. A short rope might not reach, while a long one can tangle easily.

- Measure the distance from the tree to the pulling point.

- Add extra length for knots and unexpected needs.

A rule of thumb is to have at least twice the tree height in rope length.

| Tree Height | Minimum Rope Length |

|---|---|

| 20 feet | 40 feet |

| 50 feet | 100 feet |

| 100 feet | 200 feet |

Knots And Hitches

Strong, reliable knots and hitches are crucial for pulling down trees safely. These special ties ensure that the rope holds the tree firmly. They prevent slippage and accidents. Knowing the right knots can make the difference between a successful tree pulling and a dangerous situation.

Common Knots For Tree Pulling

Choosing the right knot is key for tree pulling tasks. Some knots offer more strength and stability. They are the backbone of tree pulling work.

- Bowline Knot: Creates a fixed loop at the end of the rope. It does not slip or jam.

- Running Bowline: A noose that tightens around the tree as you pull.

- Clove Hitch: Easy to tie and untie. Good for attaching rope to a tree trunk.

- Timber Hitch: Simple and secure. Excellent for dragging logs or heavy branches.

Securing The Rope Effectively

Securing the rope is as important as choosing the right knot. A secure rope ensures control and safety.

- Inspect the rope for frays or damage.

- Choose a strong anchor point on the tree.

- Wrap the rope around the trunk several times for grip.

- Tie your chosen knot tightly and test it before pulling.

Remember: Double-check all knots before applying force. A secure setup leads to a safe tree pulling operation.

Rigging Techniques

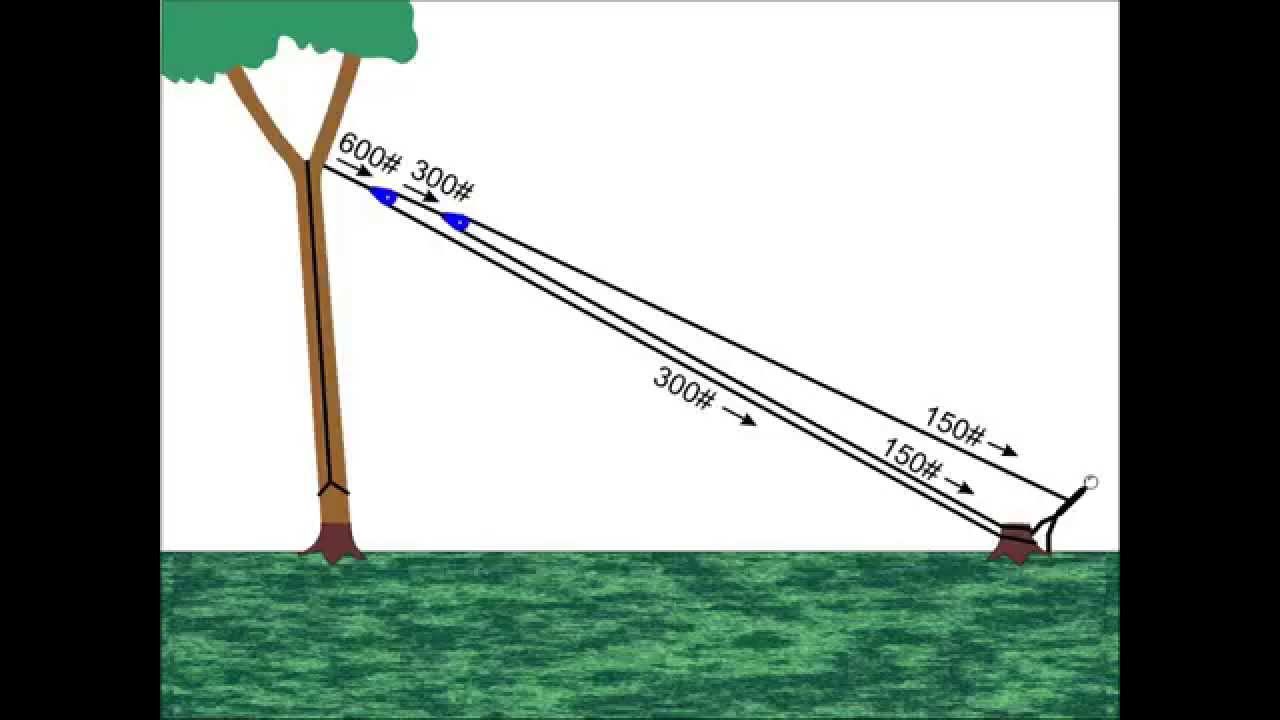

Rigging techniques are essential for safely pulling down trees. They involve the use of ropes and other equipment to control the direction and speed of the tree’s fall. This process minimizes damage to the surrounding area and ensures safety.

Mechanical Advantage Systems

Mechanical advantage systems are crucial in tree rigging. These systems use pulleys and ropes to multiply the force applied, making it easier to control heavy loads. A common setup includes:

- Pulleys to redirect the force.

- Ropes that attach to the tree.

- Anchor points that stabilize the load.

This setup allows smaller teams to manage large trees effectively.

| Component | Function |

|---|---|

| Pulleys | Reduce the effort needed |

| Ropes | Transfer force |

| Anchor Points | Provide stability |

Directional Felling

Directional felling guides the tree’s fall. Proper techniques ensure the tree lands in the right spot. Steps include:

- Choosing the fall direction.

- Creating a notch at the tree base.

- Cutting from the opposite side to guide the fall.

This method protects nearby structures and vegetation.

Maintenance And Storage

Maintenance and storage of your rope for pulling down trees matter greatly. Proper care extends its life and ensures safety. Let’s dive into the best practices for rope maintenance and how to store it correctly.

Proper Cleaning

Clean ropes after each use to remove dirt and sap. Dirt can wear down fibers over time. Use mild soap and water for cleaning. Rin’t use harsh chemicals as they can weaken the rope. Allow the rope to air-dry completely before storage. Never store a wet rope as it can develop mold or mildew.

Safe Storage Practices

Storing ropes safely is vital. Keep them away from direct sunlight as UV rays can damage the fibers. Avoid areas with high humidity. Use a rope bag or a storage container to protect the rope from pests and dust. Coil the rope loosely to prevent kinks and twists. Hang the coiled rope on a hook or place it on a shelf. This keeps the rope organized and ready for the next job.

- Never leave rope on the ground.

- Inspect for damage before and after storage.

- Keep rope away from sharp objects.

Legal And Environmental Concerns

When pulling down trees, it’s crucial to consider legal and environmental factors. These concerns help protect local ecosystems and ensure safety. Let’s dive into the specifics of compliance with regulations and minimizing ecological impact.

Compliance With Regulations

Understanding local laws is essential before pulling down trees. Each area has its own rules about tree removal. Failure to comply can lead to fines or legal issues. Always check with local authorities or a professional arborist before starting.

- Secure necessary permits

- Follow tree protection ordinances

- Adhere to property line restrictions

Some regions may require an inspection or a permit before tree removal. This ensures the tree is not protected or significant to the local environment. Always stay informed about these requirements.

Minimizing Ecological Impact

Protecting the environment is crucial when removing trees. Trees provide habitats and are vital to ecosystems. Choose methods that reduce harm to wildlife and nearby plants.

- Evaluate the area for wildlife

- Use techniques that prevent soil erosion

- Plan debris disposal carefully

Consider the impact on the soil and surrounding vegetation. Use ropes and equipment designed to minimize damage. Plan to replant trees elsewhere to maintain the area’s biodiversity.

| Action | Benefit |

|---|---|

| Using biodegradable ropes | Less waste |

| Replanting trees | Sustains habitat |

By following these steps, you can ensure a safer and more responsible tree removal process. This protects both the legal standing and the health of the local environment.

Advanced Equipment

When it comes to pulling down trees safely, advanced equipment makes the job more efficient. These tools ensure precision and control. Let’s explore the tools that professionals use.

Pulleys And Winches

Pulleys and winches are essential for heavy lifting. They multiply force, making it easier to pull down large trees. Here’s how they help:

- Force Distribution: Pulleys redirect the force applied, allowing for smoother operation.

- Load Management: Winches provide the power to pull trees with minimal effort.

| Type of Equipment | Function | Use Case |

|---|---|---|

| Static Pulley | Redirects force | Tree rigging |

| Mechanical Winch | Pulls heavy loads | Tree removal |

Rope Ascenders And Descenders

Rope ascenders and descenders are vital for climbers. They adjust climbers’ positions on the rope easily. Check their benefits:

- Quick Adjustment: Ascenders move climbers up, descenders ease them down.

- Secure Grip: Both devices lock onto the rope, preventing slips.

Here’s a comparison of the two:

| Device | Direction | Safety Feature |

|---|---|---|

| Ascender | Upward | Locking Mechanism |

| Descender | Downward | Braking System |

Training And Certification

Tackling the task of pulling down trees with rope requires not just physical strength, but also specialized training. Gaining the right knowledge and certifications ensures safety and efficiency. Professionals who undertake this work are trained to handle a variety of situations with the utmost care.

Professional Courses

Professional courses equip individuals with the necessary skills to pull down trees safely. These courses cover topics such as rope selection, knot tying, and tensioning techniques. Participants learn about the physics behind tree pulling and the importance of angle calculations and load assessment. Courses often include hands-on training sessions, providing real-life scenarios to practice these skills.

- Basic Tree Pulling Techniques

- Advanced Rigging Concepts

- Emergency Response and First Aid

- Equipment Maintenance and Safety Protocols

Certification Bodies

Certification bodies validate an individual’s capability to perform tree pulling tasks. These organizations conduct exams and practical assessments to ensure that candidates meet industry standards. Certified professionals are recognized for their expertise and adherence to safety regulations.

| Certification Body | Region | Specialization |

|---|---|---|

| International Society of Arboriculture (ISA) | Global | Tree Care and Management |

| Tree Care Industry Association (TCIA) | United States | Tree Care Safety Specialist |

| Arboricultural Association | United Kingdom | Arborist Certification |

Individuals interested in becoming certified can contact these bodies to learn about the requirements. Successful completion of the certification process provides credentials that are recognized and respected within the industry.

Case Studies

In our ‘Case Studies’ section, we delve into the experiences of individuals and companies using rope to pull down trees. These stories not only showcase the practical applications of rope but also the valuable insights gained from real-life situations. Let’s explore how rope has been instrumental in tree removal tasks.

Real-world Examples

Across the globe, ropes play a crucial role in tree removal. From small backyards to large-scale forestry operations, the strength and reliability of rope are tested. Here are a few noteworthy examples:

- Urban Tree Service: A city landscape team successfully removed a hazardous oak using a high-tensile rope system.

- Forest Management Project: Forestry experts employed ropes to safely pull down trees in a controlled burn area.

- Residential Safety: A family used rope to remove a storm-damaged pine tree leaning towards their home.

Lessons Learned

Every tree removal scenario teaches us something new. Here are some key takeaways:

- Select the Right Rope: Ensure the rope’s strength matches the task.

- Plan the Pull: Direction and force are vital for a safe tree fall.

- Safety First: Secure the area and use protective gear.

These lessons enhance safety and efficiency in tree removal with ropes.

Frequently Asked Questions

What Is The Best Rope For Pulling Trees?

The best rope for pulling trees is a polyester or nylon arborist rope, known for its strength, durability, and elasticity.

What Rope Is Used To Pull Down Tree Limbs?

For pulling down tree limbs, arborists commonly use strong, durable ropes like polyester or polypropylene. These materials ensure safety and efficiency in tree maintenance tasks.

What Is Tree Rope Called?

A tree rope is commonly referred to as an arborist rope or climbing rope.

What Is The Strongest Rope For Pulling?

The strongest rope for pulling is typically made from ultra-high-molecular-weight polyethylene (UHMWPE), known for its high strength-to-weight ratio.

Conclusion

Choosing the right rope for pulling down trees is crucial for safety and efficiency. Opt for a high-strength, durable rope that withstands heavy loads. Remember, the right tools make the job easier and safer. For more tips and product reviews, keep following our blog.

Always prioritize safety in your tree removal projects!