Rope Used for Cutting Down Trees: Essential Gear Guide

Arborists use ropes specifically designed for tree cutting. These ropes must be strong, durable, and flexible.

Contents at a Glance

ToggleTree removal is a task that requires precision and safety, where the right equipment is crucial. Cutting down trees involves ropes that are capable of handling heavy loads and withstand the rigors of outdoor work. These ropes, often made from materials like polyester or polypropylene, are engineered for strength and minimal stretch to ensure the control and security of arborists as they work at various heights.

The selection of a rope can vary depending on the size of the tree and the complexity of the job, but quality and reliability remain constant prerequisites. Safety is paramount in tree removal, and using the correct rope forms a vital part of the arborist’s toolkit, ensuring that both the individual and the tree are handled with care throughout the process.

Credit: m.petzl.com

Introduction To Arborist Ropes

Arborist ropes play a crucial role in tree cutting operations. These specialized ropes ensure safety and efficiency for arborists. They handle the rigorous demands of controlling tree limbs during removal. Different types of ropes cater to various tree cutting tasks.

| Rope Type | Features | Use Case |

|---|---|---|

| Static Rope | Low stretch, high strength | Supporting arborist’s weight |

| Dynamic Rope | High stretch, absorbs impact | Falling branches control |

| Rigging Rope | Durable, resistant to abrasion | Manipulating heavy wood |

Selecting the right rope is essential for tree cutting. Each rope type serves a specific function and enhances the arborist’s performance.

Key Features Of Tree Cutting Ropes

The strength and durability of a rope are critical for safe tree cutting. High-quality ropes resist wear and tear. They withstand harsh conditions. Look for ropes with a high tensile strength rating. This ensures they can support heavy loads without breaking.

Flexibility and knot stability are equally important in tree cutting ropes. Ropes must be flexible enough to tie secure knots. Yet, they should maintain stability under strain. A rope that holds knots well reduces the risk of slippage. This ensures the safety of arborists during tree cutting operations.

Material Choices For Arborist Ropes

Arborist ropes must endure tough conditions. Material choice is critical for safety and efficiency. Nylon ropes offer excellent elasticity, making them ideal for dynamic situations. They absorb shock well, reducing the risk of snapping under sudden loads.

Polyester, on the other hand, stands out for its low-stretch properties. It remains stable and predictable, which is essential for controlled tree cutting. Polyester ropes also resist abrasion and maintain strength even when wet.

Both materials must display UV resistance. Sunlight can weaken ropes over time. Ropes with UV inhibitors last longer, offering reliability to arborists. A rope’s longevity often depends on its ability to withstand sun damage.

Diameter And Length Considerations

Selecting the right diameter of rope is crucial. A thick rope ensures safety and efficiency. Typically, a diameter of 1/2 inch to 3/4 inch is ideal for most tree sizes. This range balances strength and flexibility.

The length of the rope also plays a vital role. For effective tree cutting, a longer rope allows more control and reach. A length of 100 to 150 feet is often sufficient. This ensures you can manage the tree from a safe distance.

Safety Ratings And Certifications

Understanding the load limits of arborist ropes is crucial for safety. Ropes have specific weight capacities they can handle. These limits are determined by rigorous testing and adherence to safety standards. It is vital that ropes used in tree cutting withstand the necessary tension. This ensures they do not fail during critical operations.

Arborist ropes must comply with industry standards. These standards are set by organizations such as the International Society of Arboriculture (ISA) and the Tree Care Industry Association (TCIA). They provide guidelines on rope strength and durability requirements. A rope’s certification indicates it has been tested and meets the minimum safety criteria. Always select ropes with proper certifications for tree cutting tasks.

Credit: chainsawacademy.husqvarna.com

Caring For Your Tree Cutting Ropes

Maintaining your tree cutting ropes ensures their longevity and safety. Clean ropes after each use to remove sap, dirt, and debris. Use mild soap and water for cleaning; avoid harsh chemicals. Allow ropes to dry fully before storing, as moisture can cause deterioration.

Proper storage is crucial for rope preservation. Coil ropes loosely to avoid kinks and stress. Store ropes in a cool, dry place away from direct sunlight. Ultraviolet rays can weaken fibers over time. Keeping ropes away from sharp objects prevents accidental cuts and abrasions.

Conduct regular inspections for frays or wear. Replace ropes as necessary to ensure optimal performance and safety. By following these tips, your ropes will be ready for the next tree cutting job.

Advanced Rope Techniques For Arborists

Arborists use special ropes for climbing trees. These ropes help them move up and down safely. Different techniques are there to use these ropes effectively.

One popular method is single rope technique (SRT), which is great for high climbs. Another method is double rope technique (DRT), used for more control during climbs.

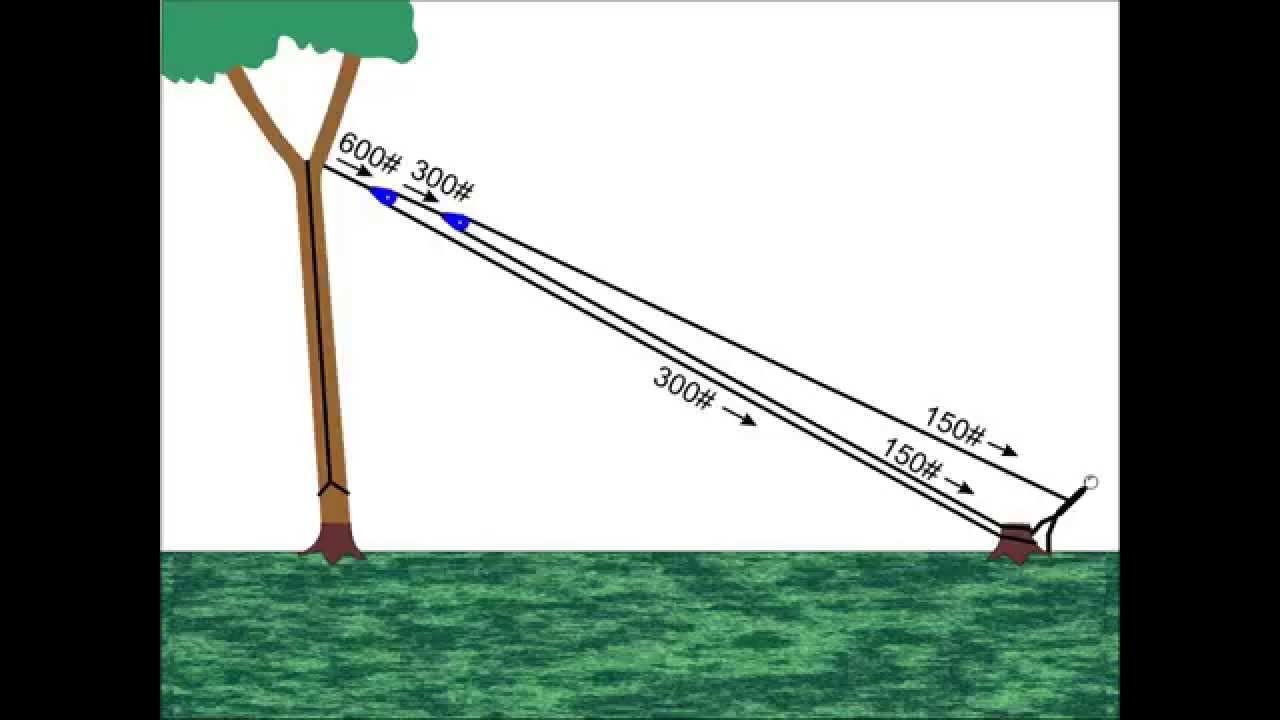

For heavy tasks, arborists use mechanical devices with ropes. These devices make the work quicker and safer. They are important for cutting down big trees without harm.

Credit: canberradiamondblade.com.au

Choosing The Right Rope For The Job

Selecting the appropriate rope for tree cutting is essential. The rope’s strength, durability, and flexibility are key factors. Safety ratings should never be overlooked. Material composition influences performance under stress. Seek ropes with resistance to weather and abrasion. Length and diameter must suit the task at hand. Ensure compatibility with other climbing gear.

Top picks include the Samson Arbor-Plex and Yale XTC Plus. These brands offer superior grip and strength. Husqvarna is another reliable choice, known for durability. Stihl ropes also come highly recommended for their quality and longevity. Each model presents unique features suited to various tree cutting scenarios.

Frequently Asked Questions

What Kind Of Rope Is Used In Tree Cutting?

Arborists typically use sturdy, static ropes designed for tree cutting, known as climbing or rigging ropes. These ropes ensure safety and efficiency during tree removal tasks.

What Is The Best Rope For Taking Down Trees?

The best rope for tree removal is a sturdy, abrasion-resistant arborist climbing rope, designed for both strength and flexibility.

What Kind Of Rope Do Loggers Use?

Loggers typically use durable, high-strength ropes such as braided polyester or polypropylene for their rigging and climbing needs. These ropes offer excellent resistance to abrasion and weather conditions, essential for the logging environment.

What Are Tree Ropes Called?

Tree ropes are commonly referred to as arborist ropes, designed specifically for tree climbing and tree care activities.

Conclusion

Selecting the right rope for tree cutting is essential for safety and efficiency. Ensure it meets industry standards and is suited for the weight and type of tree. Regular inspections and proper storage will extend its lifespan. For your next tree-cutting project, invest wisely in high-quality rope.