Metal Fitting on Which a Rope Can Be Fastened: Secure Your Load

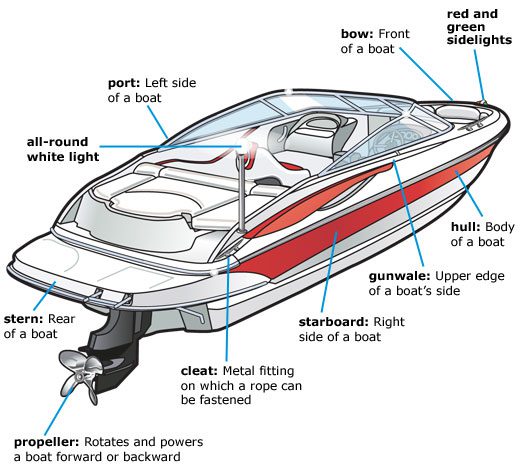

A cleat is a metal fitting on which a rope can be fastened. It’s typically a double-ended fixture used to secure lines on boats and ships.

Contents at a Glance

ToggleUnderstanding the function and importance of a cleat is essential for anyone involved in nautical activities or those interested in maritime equipment. These fittings are pivotal for mooring and securing ropes in various applications, from sailing and fishing to industrial settings.

A well-installed cleat ensures safety and efficiency, preventing ropes from slipping or coming loose under tension. They come in different sizes and materials, each suited for specific loads and environmental conditions. The design of a cleat allows for quick and secure fastening, making it a fundamental component in rigging systems. Whether you’re a seasoned sailor or someone with an interest in marine hardware, recognizing the role of cleats is crucial for maintaining proper control over your lines.

Introduction To Metal Fittings For Rope Fastening

Metal fittings are crucial for anchoring ropes securely. They play a pivotal role in ensuring safety and security. These components prevent accidents by providing a reliable attachment point for ropes. Industries like maritime, construction, and adventure sports rely on them heavily.

These fittings come in various shapes and sizes, catering to different needs. They are used in ships for mooring, in mountaineering for climbing, and on construction sites for lifting heavy loads. Their durability and strength are paramount. It’s essential to choose the right metal fitting for each application to ensure optimum performance.

| Industry | Utility of Metal Fittings |

|---|---|

| Maritime | For securing sails and mooring ships |

| Adventure Sports | For safe climbing and rappelling |

| Construction | For lifting and moving heavy materials |

Types Of Metal Fittings

Cleats are essential metal fittings used for securing rope. They feature a double-ended design, allowing for quick and easy tie-off. Cleats come in various shapes, such as horn or cam cleats, each serving a specific purpose. The design of a cleat provides stability and strength, ensuring that ropes stay in place even under tension.

Bollards, on the other hand, are robust metal posts. They are commonly found on docks for mooring ships. Their sturdy construction makes them ideal for withstanding heavy loads. Bollards often have a simple, cylindrical shape, which allows ropes to be wrapped or tied securely.

Material Considerations

Stainless steel boasts exceptional strength and longevity. This material is renowned for its ability to resist corrosion, making it ideal for marine environments where saltwater can be a concern. It’s a top choice for those needing durable metal fittings for ropes.

Galvanized iron is another solid option, offering excellent corrosion resistance. A layer of zinc coating protects the iron from rust. This makes it a reliable choice for outdoor settings, safeguarding the integrity of the rope fastening against the elements.

Load Security Techniques

Securing loads is crucial for safety and efficiency. Understanding proper knots is essential. The Bowline knot ensures a strong, reliable hold. It’s ideal for fastening ropes to metal fittings.

The Clove hitch offers easy adjustability. It’s perfect for temporary holds. Use it when constant tension is applied. Anchor bends work well for permanent fixtures. They provide a secure connection to metal points.

For even load distribution, tie a Trucker’s hitch. It allows for adjusting tension after the knot is tied. This ensures stability and reduces slippage. Always check for balanced tension across all fastened ropes.

Installation Best Practices

Installing metal fittings requires a clean and smooth surface. Prior to installation, thoroughly remove any debris or corrosion. This ensures a solid foundation for the fitting.

For heavy-duty use, select appropriate anchors and fasteners. Ensure they are capable of handling the expected load. Secure mounting is critical to prevent accidents and maintain integrity of the structure.

Credit: quizlet.com

Maintenance Tips

Regular checks for metal fittings are crucial to ensure safety. Look for signs of wear, such as rust or fraying ropes. It’s vital to catch issues early and address them promptly. Preventative care extends the life of these fittings.

Proper cleaning keeps fittings in top condition. Use gentle soap and water to remove dirt and grime. After cleaning, dry them thoroughly to prevent rust. Applying a protective coating shields against harsh weather.

Safety Precautions

Safety with metal fittings is critical. Always check the load limits before use. It’s essential to know the maximum weight each fitting can handle. Surpassing this limit can lead to failures and accidents.

Emergency release mechanisms are vital for quick disengagement. These systems allow for immediate release under tension, preventing potential hazards. It’s crucial to regularly test these mechanisms to ensure they function correctly when needed.

Credit: www.costeninsurance.com

Innovations In Metal Fittings

Metal fittings have undergone significant advancements to enhance load securing. Smart technologies now allow for real-time monitoring and adjustments to ensure stability and safety.

Leaders in the industry have embraced sustainable practices. They are integrating eco-friendly materials into their products. These materials are not only durable but also reduce environmental impact.

| Feature | Benefit |

|---|---|

| Sensors | Enhance safety |

| Recycled Metals | Lower carbon footprint |

| Automated Tensioning | Improve load stability |

Choosing The Right Fitting For Your Needs

Selecting the right metal fitting for your rope is crucial. Durability is key, as the fitting must withstand various loads. Material choice impacts resistance to corrosion and strength. Size and compatibility with the rope are vital for safety and functionality.

Usage frequency also dictates the required robustness. Seek expert recommendations to ensure the fitting meets your specific needs. They will guide you towards the most reliable options.

| Factor | Why It’s Important |

|---|---|

| Material | Defines strength and corrosion resistance |

| Size | Must match the rope for secure fastening |

| Load Capacity | Ensures the fitting can handle the weight |

| Environment | Affects the fitting’s longevity |

Credit: quizlet.com

Case Studies

Metal fittings are crucial for securing ropes in marine environments. Ships and harbors use these fittings for mooring lines. Strength and corrosion resistance are vital. The construction sector also relies on metal fittings. Safety on construction sites often depends on the reliability of these components.

| Maritime Applications | Construction Industry Solutions |

|---|---|

| Durable against saltwater | Support heavy loads and dynamic forces |

| Essential for mooring and towing | Ensure worker safety at heights |

Quality metal fittings serve diverse purposes. They are essential components in multiple industries. Their versatility and durability make them invaluable.

Frequently Asked Questions

What Is A Cleat In Sailing?

A cleat in sailing is a device for securing rope aboard boats. It is typically horn-shaped and allows for ropes to be tightly fastened without slipping. Sailors use cleats to tie off and adjust sail lines quickly and efficiently.

How Do You Use A Rope Cleat?

To use a rope cleat, wrap the rope around the base, make a figure-eight around the horns, and secure it with a final hitch. This method ensures the rope stays put under tension but can be released swiftly when necessary.

Are There Different Types Of Cleats?

Yes, there are various types of cleats including horn cleats, cam cleats, clam cleats, and jam cleats. Each type serves a specific purpose and offers different mechanisms for securing ropes, depending on the application and load.

What Are Cleats Made Of?

Cleats are typically made from materials like stainless steel, aluminum, nylon, or bronze. The choice of material depends on the cleat’s intended use and exposure to elements, balancing durability and weight.

Conclusion

Navigating the vast sea of metal fittings for ropes needn’t be daunting. Armed with knowledge from this post, you’re now equipped to choose the right fixture for your needs. Whether for marine applications, construction, or outdoor adventures, selecting the appropriate metal fitting is crucial for safety and efficiency.

Anchor your projects confidently, knowing you’ve made an informed decision.