How to Make a Rope Making Machine: Expert Guide

To make a rope making machine, you will need to gather the necessary materials and follow a step-by-step process. First, assemble a wooden frame for the machine and attach three metal hooks to hold the strands of rope.

Contents at a Glance

ToggleThen, create a rope-making mechanism using gears, pulleys, and a handle. Next, attach the mechanism to the frame, ensuring that it moves smoothly. Finally, feed the strands of rope through the hooks and turn the handle to create twisted rope.

With proper attention to detail and some basic mechanical knowledge, you can easily craft a homemade rope making machine.

Credit: www.foundationtechnologies.com

Understanding The Basics Of Rope Making

Rope making is a fascinating ancient craft that enables you to create sturdy and reliable ropes for various purposes. Whether you want to make ropes for DIY projects, gardening, or even commercial use, having a rope making machine can make the process easier and more efficient. In this guide, we will explore the basics of rope making, including the types of ropes, the materials and tools needed, and how to get started.

Types Of Ropes

Ropes come in different types, each with its unique characteristics and uses. Here are some of the most common types of ropes:

| Rope Type | Features | Uses |

|---|---|---|

| Natural Fiber Ropes | · Made from natural fibers such as hemp, manila, or jute | · Ideal for use in gardening, marine applications, and general-purpose tasks |

| Synthetic Ropes | · Made from synthetic materials like nylon, polypropylene, or polyester | · Popular in boating, camping, construction, and other outdoor activities |

| Wire Ropes | · Constructed with small metal strands twisted together | · Commonly used in heavy-duty applications like construction, mining, and lifting |

Rope Making Materials And Tools

Before you can start making ropes, you will need a few essential materials and tools. Here is a list of what you’ll need:

- Strong fibers: Natural fibers like sisal, hemp, or jute, or synthetic fibers like nylon or polyester

- Rope making machine: Either a manual machine or an electrically powered one, depending on your preference and need

- Hooks or pegs: To secure the rope during the twisting process

- Weight or tensioner: To maintain tension in the rope as it is being twisted

Having these materials and tools ready ensures you have everything necessary to make your own ropes efficiently.

Now that you have a better understanding of the basics of rope making, including the types of ropes and the materials and tools needed, you are ready to embark on your rope-making journey. In the next section, we will delve deeper into the step-by-step process of making ropes using a rope making machine.

Building Your Own Rope Making Machine

Learn how to create your own rope making machine with this comprehensive guide. Discover step-by-step instructions and tips for constructing a machine that will allow you to produce your own ropes efficiently and effectively.

Design Considerations

When designing your rope making machine, there are a few important factors to consider. Firstly, you need to determine the size and type of rope you will be making. This will impact the dimensions and specifications of the machine. Additionally, you should consider the materials you will be using for the machine’s construction. It is crucial to use durable and sturdy materials that can withstand the stress of rope making. Finally, think about the ease of use and maintenance of your machine. You want to ensure that it is user-friendly and requires minimal maintenance to maximize efficiency.

Step-by-Step Construction Process

Creating your rope making machine may seem daunting at first, but with a step-by-step approach, it can be a manageable project. Here is a breakdown of the construction process:

1. Gather the necessary materials:

– Steel rods or pipes for the frame

– Gears and pulleys for the rotating mechanism

– Bearings for smooth motion

– Bolts, nuts, and washers for assembling the components

– A strong motor to provide power

2. Build the frame:

– Cut the steel rods or pipes according to your desired dimensions

– Assemble the frame by welding or using strong bolts and nuts

– Ensure the frame is sturdy and stable to support the rotating mechanism

3. Install the rotating mechanism:

– Attach the gears and pulleys to the frame

– Place the bearings on the frame to allow smooth rotation

– Connect the gears and pulleys using a belt or chain to transfer power

4. Add the rope guides and tension mechanism:

– Install rope guides at strategic positions to guide the rope during the making process

– Incorporate a tension mechanism to control the tightness of the rope

5. Integrate the motor:

– Mount the motor securely on the frame

– Connect the motor to the rotating mechanism to provide power

6. Test and adjust:

– Ensure all components are securely fastened and aligned

– Test the machine with a small amount of rope to check for any adjustments needed

– Make any necessary tweaks to optimize its performance

By following this step-by-step construction process, you will be able to build a rope making machine that is tailored to your specific needs. Keep in mind that safety should always be a priority when working with machinery. Make sure to wear appropriate protective gear and consult a professional if needed. Now that the construction process is complete, you are ready to start making your own ropes with your newly built machine!

Using And Maintaining A Rope Making Machine

Using and maintaining a rope making machine is essential for ensuring its longevity and obtaining high-quality rope production. Proper operation of the machine, routine maintenance, and troubleshooting are key aspects that need to be considered. This section will guide you through the process of operating the machine, performing routine maintenance, and troubleshooting common issues.

Operating The Machine

Operating a rope making machine requires a basic understanding of its components and functions. Here is a step-by-step guide to help you operate the machine effectively:

- Before starting, ensure that all safety precautions are in place, including wearing appropriate protective gear.

- Inspect the machine for any visible damage or worn parts. If any issues are detected, they should be addressed before proceeding.

- Prepare the raw material, such as fiber or yarn, by measuring and cutting it to the desired length.

- Attach the material securely to the feeding mechanism of the machine, ensuring it is aligned properly.

- Activate the machine’s power source and adjust the speed settings according to the thickness and type of rope you intend to produce.

- Monitor the rope-making process closely, ensuring that the material is fed consistently and evenly into the machine.

- Collect the produced rope carefully, avoiding any tangles or knots, and store it appropriately.

- After completing the production, switch off the machine and perform a final inspection to check for any irregularities or issues.

Routine Maintenance And Troubleshooting

To keep your rope making machine functioning smoothly, regular maintenance and prompt troubleshooting are essential. Here are some routine maintenance tasks and troubleshooting tips:

Routine Maintenance:

Perform these tasks as part of your routine maintenance schedule:

- Regularly clean the machine to remove any debris or dust that may accumulate during the production process.

- Check and tighten any loose bolts or fasteners to ensure stability and prevent vibrations.

- Inspect the machine’s moving parts, such as gears and pulleys, for signs of wear or damage. Replace any worn-out parts promptly.

- Apply a suitable lubricant to the machine’s moving parts to reduce friction and increase longevity.

- Keep the machine’s electrical components clean and free from moisture.

Troubleshooting:

If you encounter any issues with your rope making machine, consider the following troubleshooting steps:

| Issue | Possible Solutions |

|---|---|

| The machine is jammed or not feeding material properly. | Check for any obstructions in the feeding mechanism and remove them. Adjust the tension settings if necessary. Inspect the material for any knots or tangles. |

| The produced rope is uneven or of poor quality. | Ensure that the material is fed consistently and evenly. Adjust the machine’s speed settings if needed. Inspect and replace any worn-out components that may affect the rope quality. |

| The machine is making unusual noises. | Check for loose or damaged parts, including belts and gears. Tighten or replace as necessary. Apply lubrication to reduce friction. |

| The machine is not powering on. | Check the power source and connections. Replace any faulty electrical components. Ensure the machine is properly grounded. |

By following the proper operating procedures, performing routine maintenance, and addressing any troubleshooting issues promptly, you can ensure optimal performance and longevity of your rope making machine.

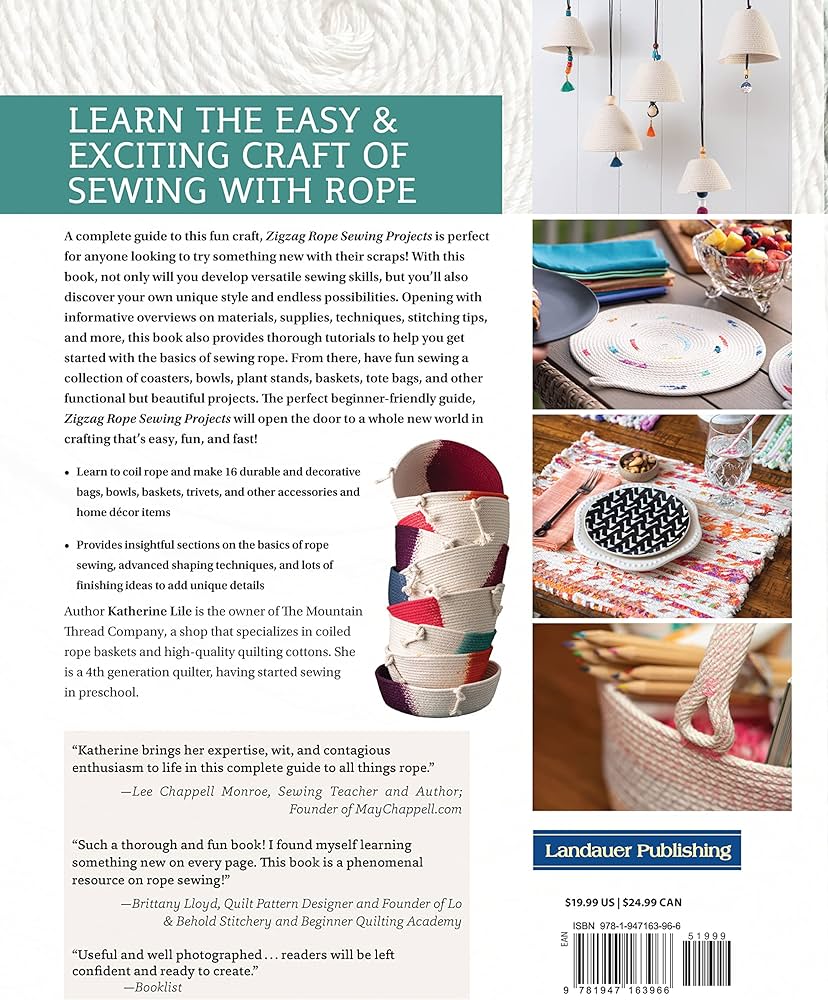

Credit: www.amazon.com

Frequently Asked Questions For How To Make A Rope Making Machine

How Can I Build A Rope Making Machine At Home?

To build a rope making machine at home, you will need some basic tools and materials such as wood, screws, pulleys, and a drill. Follow the step-by-step instructions in our blog post to easily construct your own rope making machine and start creating ropes right in your own workshop.

What Are The Benefits Of Making Your Own Rope?

Making your own rope has several benefits. Firstly, it allows you to customize the rope’s length and strength according to your specific needs. Secondly, it is a cost-effective solution compared to buying rope from a store. Additionally, crafting your own rope can be a fulfilling and enjoyable DIY project that encourages creativity and self-reliance.

Can I Use Different Types Of Fibers To Make Rope?

Absolutely! You can use a wide range of natural or synthetic fibers to make rope, depending on your desired application or preference. Common options include cotton, hemp, nylon, sisal, or even recycled materials like t-shirts or plastic bags. Experiment with different materials to achieve the desired texture and strength for your ropes.

Conclusion

Creating your own rope making machine is not only a fascinating project but also a cost-effective solution for anyone in need of quality ropes. By following the step-by-step instructions provided in this blog post, you can now embark on your journey to making ropes with ease.

Crafting your own ropes not only allows for customization but also provides a sense of accomplishment. So, gather your materials and get ready to discover the joy of making ropes with your very own rope making machine!