What is the Recommended Type of Wire Rope Clamp?

Are you navigating the intricate world of wire rope clamps, trying to find the ideal choice for your specific needs? Look no further. Many options await in the realm of rope clamps, from traditional metal rope clamps to versatile adjustable and specialized climbing rope clamps. The selection process can be daunting, but fear not, for we are about to unravel the intricacies.

Contents at a Glance

ToggleWhether securing a heavy load or ascending to new heights, understanding the nuances of nylon rope clamps and mastering how to use a rope clamp is paramount. Join us as we delve into the world of rope clamps, providing insights and recommendations to empower your decision-making. Unlock the potential of this essential tool with our comprehensive guide and explore the possibilities a rope clamp kit can offer. Your journey to rope-clamping excellence begins here.

What Does Wire Rope Clamp Mean?

At its core, a wire rope clamp is designed to clamp down on a wire rope, creating a connection point or termination. This prevents the rope from slipping or coming undone, ensuring the safety of both personnel and valuable equipment. Wire rope clamps are typically made from steel or stainless steel, ensuring durability and longevity.

How Strong Are Rope Clamps?

The strength of a rope clamp is measured by its tensile strength, which is the force it can withstand before breaking. The tensile strength of a rope clamp is typically determined by its size. Here is a chart of the strength of common rope clamp sizes:

| Rope Clamp Size | Tensile Strength (lbs) |

| 1/4″ | 750 |

| 3/8″ | 1000 |

| 1/2″ | 1500 |

| 5/8″ | 2000 |

| 3/4″ | 3000 |

It is important to note that the tensile strength of a rope clamp is only a guideline. The strength of a rope clamp will also depend on the quality of the materials used, how the clamp is installed, and the environment in which it is used.

For example, a rope clamp made of high-quality materials and installed properly will be stronger than a clamp made of low-quality materials or installed incorrectly. Additionally, a rope clamp used in a corrosive environment, such as near salt water, will need corrosion-resistant materials.

What Are the Different Types of Rope Clamps?

Wire rope clamps come in various types, each suited to specific applications. Let’s explore some of the most common types:

1. Basic Rope Clamp

The rope clamp is versatile and easy to install, a general-purpose clamp used in a wide range of applications. It provides a secure grip on the wire rope, preventing slippage.

Features:

- Tensile strength: The force a rope clamp can withstand before breaking.

- Working load limit: The maximum weight a rope clamp can safely support.

- Material: Rope clamps are typically made of steel, aluminum, or stainless steel.

- Finish: Rope clamps can be finished in various ways, including zinc plating, hot-dipped galvanizing, and powder coating.

- Design: Rope clamps come in various designs, including screw-down clamps, cam-action clamps, and wedge clamps.

- Application: Rope clamps are used in various applications, including lifting, rigging, and securing loads.

- Safety: Rope clamps should always be used under the manufacturer’s instructions to ensure safety.

2. Wire Rope Clamp

This clamp type is specifically designed for wire ropes and provides a robust grip. It’s commonly used in heavy-duty applications.

Features:

- Strong and durable: Wire rope clamps are made of high-quality materials, such as steel or aluminum, that can withstand much force.

- Secure fastening: Wire rope clamps provide a secure fastening for wire ropes, preventing them from slipping or coming loose.

- Easy to use: Wire rope clamps are relatively easy, even for people with limited DIY skills.

- Versatile: Wire rope clamps can be used in various applications, such as hoisting, lifting, and securing loads.

- Weatherproof: Wire rope clamps are typically weatherproof, making them suitable for use in outdoor applications.

- Cost-effective: Wire rope clamps are a cost-effective way to secure wire ropes.

3. Metal Rope Clamp

Metal rope clamps are built to handle extreme loads. They are often used in industrial and marine environments where strength is paramount.

Features:

- Strong and durable: Metal rope clamps are made of strong and durable materials, such as steel or aluminum. This makes them ideal for demanding applications, such as lifting, rigging, and securing loads.

- Wide range of sizes: Metal rope clamps are available in a wide range of sizes, so you can find the right size for your application.

- Easy to use: Metal rope clamps are easy to use. Simply slide the clamp onto the rope and tighten the screw.

- Reusable: Metal rope clamps are reusable so you can use them repeatedly.

- Corrosion-resistant: Metal rope clamps are made of materials resistant to corrosion in harsh environments.

- Safe: Metal rope clamps are designed to be safe to use. They have a locking mechanism that prevents them from coming loose.

4. Adjustable Rope Clamp

As the name suggests, adjustable rope clamps allow for flexibility regarding rope size and tension. They are ideal for situations where adjustments may be required.

Features:

- Adjustable: The clamp can be adjusted to fit different sizes of ropes.

- Durable: The clamp is made of high-quality materials resistant to corrosion and wear and tear.

- Secure: The clamp provides a secure hold on the rope, even under heavy loads.

- Easy to use: The clamp is easy to install and remove.

- Versatile: The clamp can be used for various applications, such as securing ropes to poles, beams, and other objects.

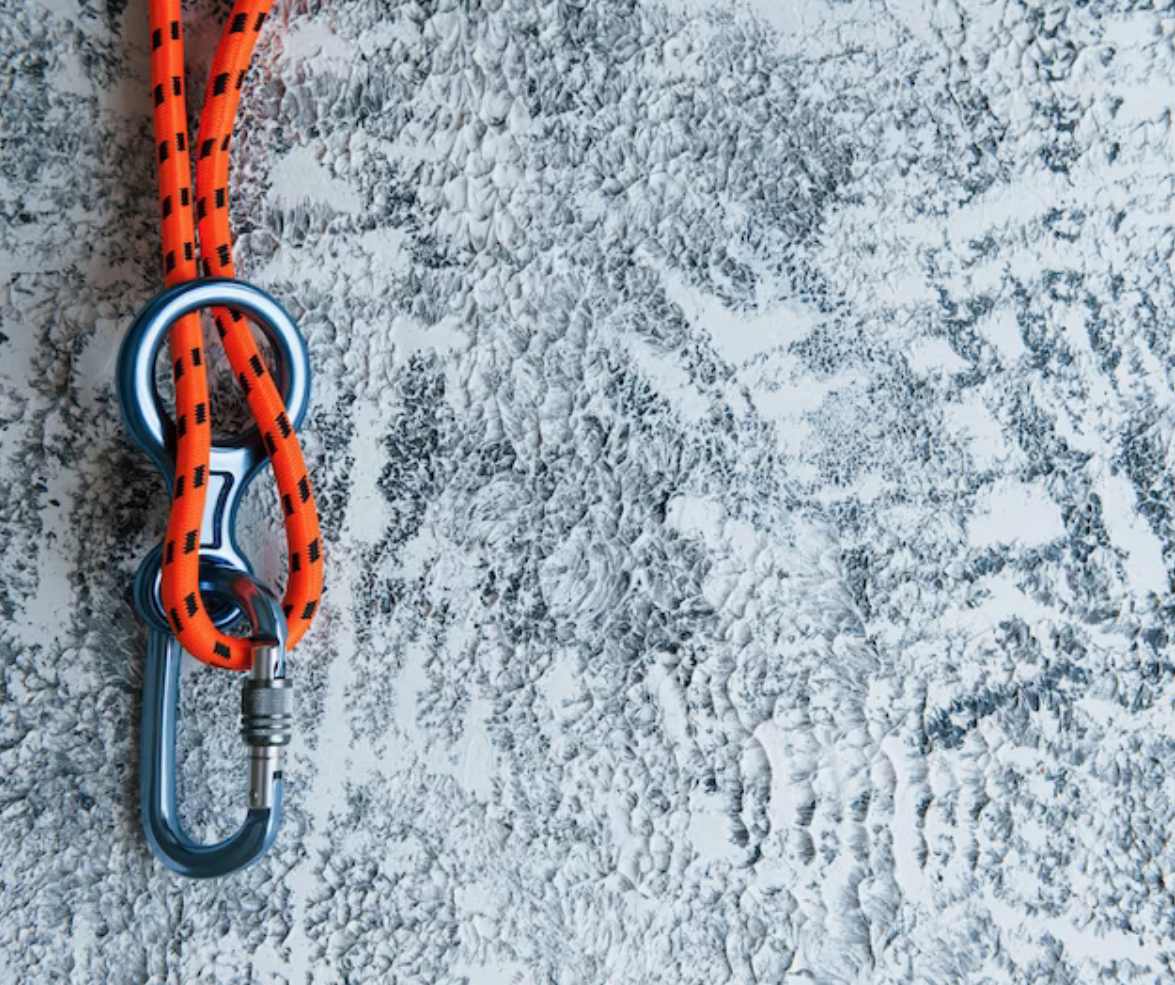

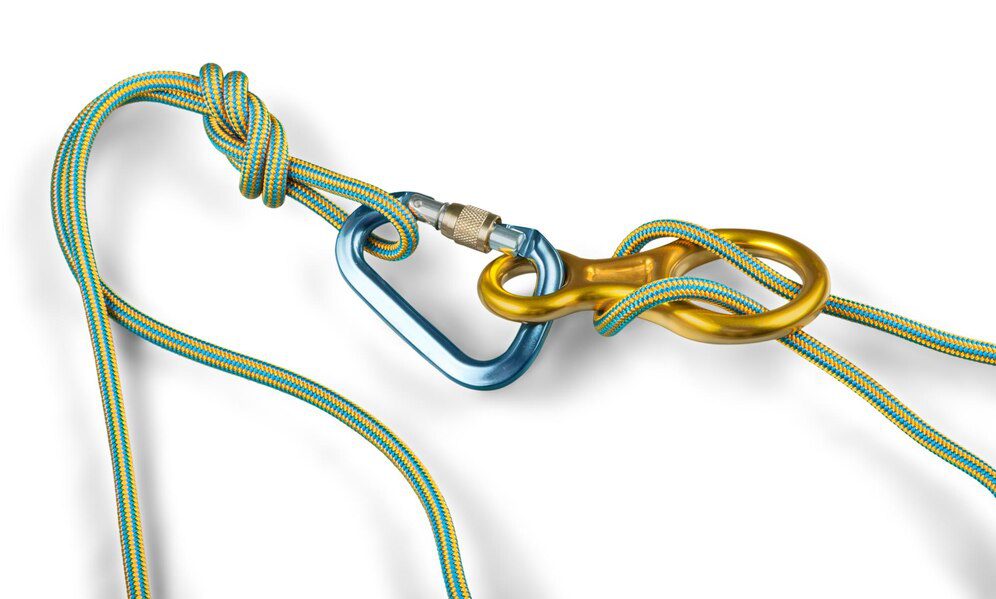

5. Climbing Rope Clamp

In rock climbing and mountaineering, climbing rope clamps offer the security needed in high-risk situations. They are designed to withstand dynamic loads and ensure climber safety.

Features:

- Tensile strength: The ability of a rope clamp to withstand a pulling force without breaking.

- Working load limit: The maximum weight a rope clamp can safely support.

- Material: The type of material that the rope clamp is made of, such as steel, aluminum, or plastic.

- Size: The diameter of the rope that the rope clamp can accommodate.

- Design: The shape and construction of the rope clamp affect its strength, ease of use, and compatibility with different ropes.

- Finish: The coating or surface treatment of the rope clamp, which can protect it from corrosion and wear.

- Color: The color of the rope clamp can be a matter of personal preference or may be required for safety reasons.

- Price: The cost of the rope clamp can vary depending on the features and materials used.

6. Nylon Rope Clamp

Nylon rope clamps are lightweight and corrosion-resistant, making them suitable for marine and outdoor applications.

Features:

- Made of high-quality nylon that is strong, durable, and weather-resistant.

- UV-resistant and will not fade or crack in the sun.

- Low-stretch construction provides a secure hold on the rope.

- Easy to use, slide the clamp over the rope and tighten the screw.

- Available in a variety of sizes to accommodate different ropes.

- Can be used for a variety of applications, such as rigging, securing loads, and making repairs.

How to Use a Rope Clamp

Using a rope clamp correctly is essential for ensuring a secure connection. Here’s a step-by-step guide:

- Prepare the Wire Rope: Ensure the wire rope is properly looped or attached to the object.

- Position the Clamp: Place the clamp over the loose end of the wire rope.

- Tighten the Nuts: Use a wrench to tighten the nuts on the clamp evenly. Ensure that the clamp is secure but not over tightened.

- Inspect the Connection: Check the connection for any slippage or irregularities. Make necessary adjustments if required.

What is Rope Clamp Climbing?

Rope clamp climbing is often used in industrial rope access work, where workers need to ascend and descend ropes to reach difficult-to-access areas. It can also be used for recreational climbing, such as ascending a cliff face or rappelling down a mountain.

You will need a rope clamp, a carabiner, and a harness to climb with rope clamps. You must also be trained properly using rope clamps and safety procedures.

To ascend with rope clamps, you first attach the rope clamp to the rope with a carabiner. Then, you clip the rope clamp to your harness. To climb, you move the rope and clamp up the rope by hand. The cam or ratchet mechanism will grip the rope and prevent it from slipping.

Attach the clamp to your harness to descend with rope clamps and then rappel down the rope. When rappelling, the rope clamp automatically locks in place when you are not moving.

Rope Clamp Kit

Many manufacturers offer rope clamp kits with all the necessary components for a secure and reliable connection. These kits often include clamps, nuts, and sometimes thimbles for added protection.

There are two main types of rope clamp kits:

- Spring clamps are made of a spring-loaded metal clip that opens and closes around the rope. They are easy to use and can be adjusted to fit various rope sizes. However, they are not as strong as other rope clamps and can be damaged if the rope is too thick or heavy.

- Clevis clamps are made of a metal clevis with a threaded bolt. The bolt is inserted through the rope and tightened to secure the clamp. Clevis clamps are more secure than spring clamps and can be used with thicker and heavier ropes. However, they are more difficult to use and require a wrench or socket wrench to tighten the bolt.

In addition to these two main types, there are also a variety of other rope clamp kits available, such as:

- Adjustable rope clamps can be adjusted to fit a range of rope sizes.

- Nylon rope clamps are made of nylon and are less likely to damage the rope than metal clamps.

- Stainless steel rope clamps are corrosion-resistant and can be used in outdoor applications.

What Are the Clamps Used for Rope?

Clamps used for rope, including wire rope clamps, are employed in a wide range of applications, including:

- Lifting and Rigging: Wire rope clamps are essential in lifting heavy loads safely.

- Maritime: Wire rope clamps secure ropes on ships and offshore installations in the marine industry.

- Construction: Construction sites use wire rope clamps to secure loads and scaffolding.

How Many Wire Rope Clamps to Use?

The number of wire rope clamps to use depends on the diameter of the wire rope and the specific application. As a general rule of thumb, using at least three clamps for wire ropes up to 1/2-inch diameter and an additional clamp for each 1/4-inch increase in diameter is recommended. Always refer to manufacturer guidelines and industry standards for precise recommendations.

Here are some examples of how many wire rope clamps to use:

| Wire Rope Size (in) | Minimum Number of Clamps |

| 1/4 | 3 |

| 3/8 | 4 |

| 1/2 | 5 |

| 5/8 | 6 |

| 3/4 | 7 |

| 1 | 8 |

It is important to note that these are just general guidelines. The specific number of wire rope clamps that need to be used should be determined by a qualified rigging professional.

Final Thoughts

In the world of rigging and climbing, the choice of wire rope clamp can make all the difference in safety and performance. Whether you’re working with a sturdy metal rope or a reliable nylon one, the right clamp can be the linchpin of your setup. While there are various options, like the versatile adjustable rope clamp and specialized climbing rope clamp kits, the ideal choice ultimately hinges on your specific needs and circumstances. To ensure your equipment is up to the task, always refer to manufacturer guidelines and expert advice on how to use a rope clamp effectively. So, whether you’re scaling peaks or securing heavy loads, decide wisely and elevate your endeavours to new heights with the right rope clamp.

FAQs

- Are wire rope clamps reusable?

- Wire rope clamps can be reused if they are in good condition and not under excessive stress. Regular inspections are essential to ensure their continued reliability.

- What is the difference between a rope clamp and a wire rope clamp?

- While both clamps serve similar purposes, a rope clamp is a more generic term and can refer to clamps used for various types of ropes. Wire rope clamps are specifically for wire ropes.

- Can wire rope clamps be used in corrosive environments?

- Wire rope clamps are commonly made of stainless steel or other corrosion-resistant materials, which makes them suitable for use in corrosive environments.

- Do I need to lubricate wire rope clamps?

- It’s generally not necessary to lubricate wire rope clamps, but it can help reduce friction during installation. Use a lubricant recommended by the manufacturer.

- What is the maximum load capacity of wire rope clamps?

- The maximum load capacity varies depending on the size and type of wire rope clamp. Always refer to the manufacturer’s specifications for load capacity information.